New products added daily!

Laser Cutting Acrylic & Laser cutting plastic

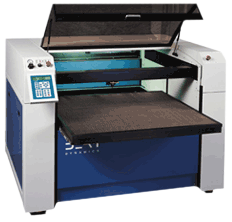

Hamlet Products can laser cut acrylic parts to your specifications. When you need laser cutting or laser etching, but don't have the machines available, contact Hamlet.We have five state-of-the art lasers, which operate from 50 to 500 watts and can cut at a tolerance of .001.

Assembly services are also available. Please contact us for more information.

laser cutting machine

If you need laser cutting acrylic for commercial use then you’ll probably want to find a company whose business is laser cutting acrylic. Hamlet Products is in the business of doing just that.

Common Questions About Working with Acrylic

Acrylic is great material to work with because of the creation process, durability, and final products they create. Working with acrylic is done on an industrial sized scale, but can also be worked on at home for D.I.Y projects. For anyone looking to work with acrylic, it is important you find and hire a professional company. This is so you deal with individuals who have the tools/machinary and knowledge to do perfect acrylic cutting and tapping. Most of the professional machines used too cut acrylic (i.e. a water-jet cutter) are rather expensive a difficult to learn to use properly. Dealing with professional companies will save time and money in the long run.

Below we will be going over some common questions that are asked when working with acrylic.

Q) Is it possible to bend acrylic?

A) The simple answer is yes. When heated to the proper temperature, acrylic becomes malleable. When it is cooled it returns to its hardened state. This is not an easy process, and so it requires special tools and knowhow. Depending on the length and width of the piece, different heat needs to be applied for different times. If overheated, the acrylic can melt or completely warp. It is also difficult to actually bend and hold a shape, so professional companies have expensive systems designed specifically to bend acrylic. This will ensure that your acrylic is bent to the proper angles/dimensions.

Q) Can you glue acrylic to another piece of acrylic?

A) It is possible to use glue, but there are different types of acrylic glue to choose from. This includes acrylic cement and water thin cements. Thicker cement will fill voids between pieces of acrylic, but do not allow for a perfectly flush finish. A thin cement well help to make perfect joints, but it will not fill in any gaps. If your product is finished properly, then it is much easier to determine the best type of glue for you.

Q) Can acrylic be glued to glass?

A) General Electric makes something called contractors silicone (also known as SCS 1200), and it is commonly used when gluing glass and acrylic. It is best to leave this to professionals as well. In order to make a perfect, seamless bond both surfaces must be perfectly clean. Even a simple fingerprint can ruin the bonding process. Professionals can get a perfect bond every time.

Related Reading

- What Is Laser Cutting Acrylic?Laser cutting is an incredible process in which lasers are used to cut materials, such as acrylic and metal.

- Advantages of Laser Cutting

In fact, laser cutting acrylic is the most common cutting method for this plastic. Laser cutting requires less time than other forms of cutting. Cutting with lasers will drastically reduce the risk of contaminating materials.

- Materials for laser cutting acrylicLaser cutting acrylic is an extremely popular method for custom designing products. The process of laser cutting acrylic allows designers to create a multitude of products.

- Why is Laser Cutting Important?For more information about laser cutting acrylic, please let us be your first call. Let us help you design custom acrylic displays with the help of lasers.

- Dealing with Scratched Acrylic

- A Friend In Acrylic Laser Cutting

- What is Acrylic and How is it Made?

- Acrylic Display Cases

- Non-traditional uses for Acrylic

- Commercial

- Residential

- Different types of Acrylic Displays

- Recycling Acrylic

- Using Lasers to Cut Plastic

- Different Styles of Acrylic Holders

- How to Protect Acrylic

- Acrylic or Glass Display Cases

- Recycling Acrylic Plastic

- Acrylic Displays and Business

- Custom Acrylic Table Toppers

- Many different uses for Acrylic

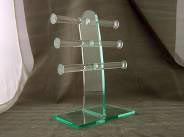

- Custom Acrylic Displays

- Custom Acrylic Sign in Books

- Customization with Acrylic Cutting

- Custom Laser Engraving

- Custom Theater Gifts

- CO2 Laser Cutting Acrylic

- Custom Acrylic Makes a Great Gift

- Acrylic is the Superior Material

- Precision Cutting Acrylic with Lasers

- Solutions for Displaying Products

- Wide Range of Applications for Laser Cut Acrylic

- Difference Between Different Types of Display Cases

- How Lasers Have Changed

- Understanding Acrylic Plastic

- Why and how Acrylic Plastic is Used

- Top Reasons to Consider Acrylic Plastic

- Acrylic Box Options

- Acrylic Instead of Glass

- Benefits of CNC Routing

- Incorporating Acrylic Into Your Wedding Planning

- Reasons to Consider Laser Cutting Acrylic

- Reasons to Consider Acrylic Plastic over Glass

- Why Should a Business Use Business Cards and Business Card Holders?

- Is Acrylic Better than Glass

- Custom Acrylic Invitations

- What is Acrylic Plastic?